1. Inngangur

This manual provides essential information for the safe and efficient operation, maintenance, and setup of your JET GH-2280ZX 22" x 80" Geared Head Metal Lathe. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent injury or damage.

The JET ZX Series Large Spindle Bore Lathe is designed to deliver power, precision, efficiency, and reliability for metalworking applications. Key features include a one-piece cast iron base for vibration absorption, a universal gearbox, and safety enhancements like an e-stop on the carriage.

Mynd 1: Fullt view of the JET GH-2280ZX Geared Head Metal Lathe.

2. Öryggisleiðbeiningar

Always prioritize safety when operating machinery. Failure to follow safety guidelines can result in serious injury or death. This section outlines general safety practices. Refer to the full safety manual (if provided separately) for comprehensive details.

- Lestu handbókina: Skiljið allar leiðbeiningar og viðvaranir fyrir notkun.

- Notið persónuhlífar (PPE): Always wear safety glasses, hearing protection, and appropriate clothing. Avoid loose clothing, jewelry, and long hair.

- Vinnusvæði: Haltu vinnusvæðinu hreinu, vel upplýstu og lausu við hindranir.

- Ástand vélarinnar: Inspect the lathe for damage or loose parts before each use. Ensure all guards are in place.

- Neyðarstopp: Familiarize yourself with the location and operation of the emergency stop button. The GH-2280ZX features an e-stop on the carriage for increased operator safety.

- Rafmagnstenging: Disconnect power before performing any maintenance, adjustments, or when changing accessories.

- Öruggt vinnustykki: Gakktu alltaf úr skugga um að vinnustykkið sé vel festamped in the chuck or between centers.

- Proper Tooling: Use only sharp, correctly ground cutting tools suitable for the material being machined.

3. Uppsetning og uppsetning

Proper setup is crucial for the performance and safety of your lathe. Due to the weight and complexity of this machine, professional installation is recommended.

3.1 Upptaka og staðsetning

The JET GH-2280ZX weighs approximately 6933 pounds. Ensure the installation location has a solid, level foundation capable of supporting this weight. Use appropriate lifting equipment for unpacking and positioning.

- Fjarlægið varlega öll umbúðaefni.

- Skoðið vélina fyrir flutningsskemmdir. Tilkynnið flutningsaðila og birgja tafarlaust um allar skemmdir.

- Position the lathe in an area with sufficient space for operation and maintenance, ensuring adequate clearance around all moving parts.

- Level the machine using shims under the base as necessary.

3.2 Rafmagnstenging

This machine requires a 3-phase, 230/460V power supply. Electrical connections must be performed by a qualified electrician in accordance with all local and national electrical codes.

- Staðfestu binditage and phase of your power supply match the machine's requirements.

- Gakktu úr skugga um rétta jarðtengingu.

- Install appropriate circuit protection.

3.3 Uppsetning íhluta

Install included accessories such as the 10" 3-Jaw Chuck, 12" 4-Jaw Chuck, Steady Rest, and Follow Rest as needed for your specific operations. Refer to the detailed diagrams in the full product manual for precise installation steps.

Figure 2: The JET GH-2280ZX lathe with various components and accessories installed.

4. Notkunarleiðbeiningar

Understanding the controls and functions of your lathe is essential for safe and effective operation.

4.1 Stjórnborð yfirview

The lathe features centrally-located controls for ease of use. Familiarize yourself with the main power switch, emergency stop button, spindle speed selectors, and feed controls.

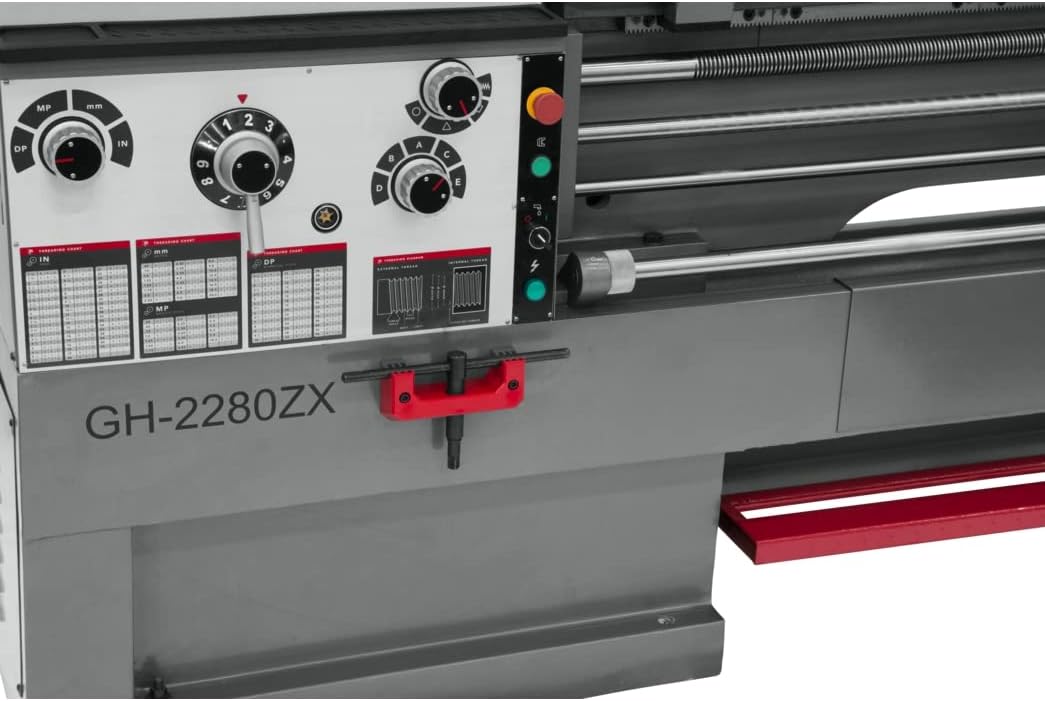

Mynd 3: Nærmynd view of the main control panel with various dials and buttons.

4.2 Spindle Operation

The 3-1/8" bore spindle is supported by two tapered and one ball bearing. Use the spindle speed selectors to choose the appropriate RPM for your material and cutting tool. Always ensure the chuck or faceplate is securely mounted before starting the spindle.

Mynd 4: View of the chuck and headstock area, showing the spindle and chuck guard.

4.3 Carriage and Tool Post

The carriage allows for longitudinal and cross-feeding operations. The GH-2280ZX features a five-position automatic carriage stop for increased productivity and precision. The tool post holds the cutting tools securely.

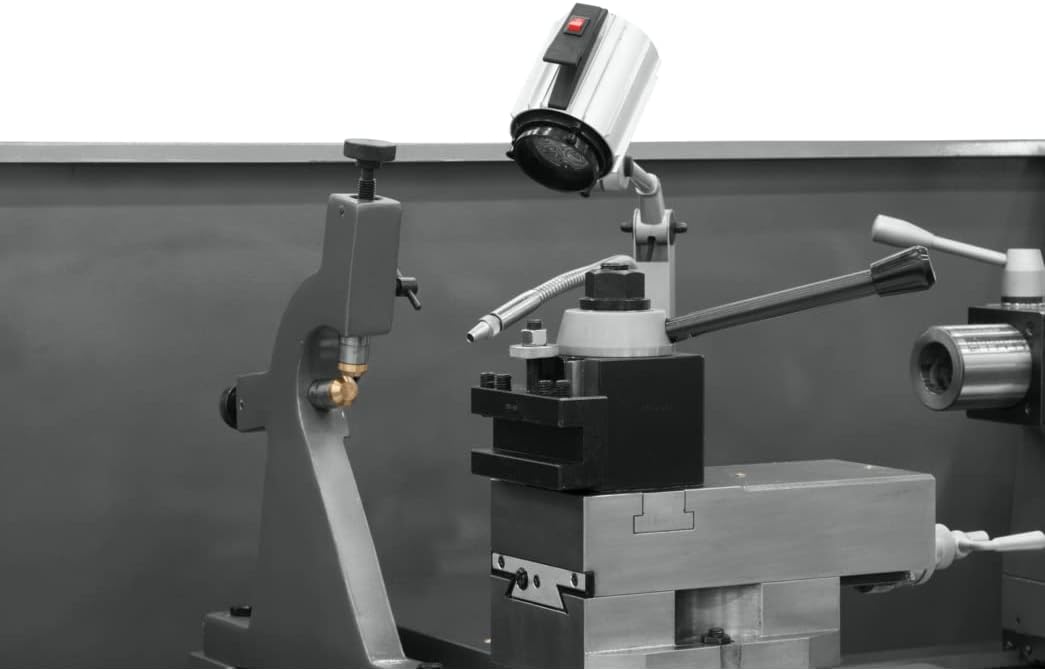

Mynd 5: Ítarleg view of the carriage, tool post, and lead screw.

4.4 Threading Operations

The universal gearbox eliminates the need for manual gear changes, allowing for easy selection of inch, metric, diametral, and module pitch threads. Consult the threading chart on the machine for correct settings.

4.5 Coolant System

The fully-integrated coolant system includes a full-length splash guard and coolant return, contributing to a cleaner work environment and improved tool life. Ensure the coolant reservoir is filled with appropriate cutting fluid.

Figure 6: Work light and coolant nozzle positioned near the cutting area.

4.6 Bakkútur

The tailstock is used to support long workpieces or to hold drilling and reaming tools. Ensure it is properly aligned and locked in position before use.

Mynd 7: Ítarleg view of the tailstock assembly.

5. Viðhald

Regular maintenance ensures the longevity and optimal performance of your JET GH-2280ZX lathe. Always disconnect power before performing any maintenance.

- Þrif: After each use, clean chips and debris from the bed, carriage, and other surfaces. Use a brush or shop vacuum; never use compressed air to blow chips towards yourself or others.

- Smurning: Regularly lubricate all moving parts, including the lead screw, feed rod, and gearbox components, according to the lubrication schedule provided in the comprehensive manual.

- Skoðun: Periodically inspect belts, gears, and electrical connections for wear or damage. Replace worn components as necessary.

- Kælivökvakerfi: Clean the coolant tank and filter regularly to prevent buildup and maintain coolant effectiveness.

6. Bilanagreining

Þessi hluti veitir almennar leiðbeiningar um algeng vandamál. Hafðu samband við hæft þjónustufólk ef um flókin vandamál er að ræða.

| Vandamál | Möguleg orsök | Lausn |

|---|---|---|

| Vélin fer ekki í gang | No power, emergency stop engaged, circuit breaker tripped. | Check power supply, disengage e-stop, reset circuit breaker. |

| Of mikill titringur | Unbalanced workpiece, loose mounting, worn bearings, improper cutting conditions. | Balance workpiece, tighten mounting bolts, inspect bearings, adjust cutting speed/feed. |

| Léleg yfirborðsáferð | Dull cutting tool, incorrect speed/feed, excessive tool overhang, machine chatter. | Sharpen/replace tool, adjust speed/feed, reduce tool overhang, check machine rigidity. |

7. Tæknilýsing

Key technical specifications for the JET GH-2280ZX Geared Head Metal Lathe:

| Forskrift | Gildi |

|---|---|

| Gerðarnúmer | GH-2280ZX |

| Framleiðandi | Þota |

| Snælda bora | 3-1/8 tommur |

| Aflgjafi | Rafmagn með snúru |

| Voltage | 230 Volts (3-Phase) |

| Hestöfl | 10 HP |

| Þyngd hlutar | 6933 pund |

| Vörumál | 136 x 45 x 69 tommur |

| Efni | Steypujárn |

| Innifalið íhlutir | Lathe, Steady Rest, Follow Rest, 10" 3-Jaw Chuck, 12" 4-Jaw Chuck, Tool Box (with tools) |

8. Upplýsingar um ábyrgð

The JET GH-2280ZX Geared Head Metal Lathe is backed by a 2 ára ábyrgð. This warranty covers defects in materials and workmanship under normal use. For specific terms, conditions, and claim procedures, please refer to the official JET warranty documentation or contact JET customer support.

Figure 8: JET Red Assurance 2-Year Warranty.

JET also performs a 30 punkta skoðun on its products to ensure quality and reliability.

Figure 9: JET Red Assurance 30 Point Inspection.

9. Þjónustudeild

For technical assistance, parts, or service inquiries regarding your JET GH-2280ZX lathe, please contact JET customer support. You can typically find contact information on the official JET webá staðnum eða í umbúðaefninu.

Heimsæktu embættismanninn JET Store fyrir frekari upplýsingar og vöruúrræði.